Sep 19,2023 by DAWN

HNBR Rubber is A Kind of High-Quality Material for Optimal Performance

When it comes to high-performance rubber materials, HNBR rubber is one of the most versatile choices for a wide range of applications. This rubber material is known for its superior mechanical properties, resistance to temperature and chemicals, and excellent compatibility with various fluids.

HNBR stands for hydrogenated nitrile butadiene rubber, which is a synthetic rubber material derived from butadiene and acrylonitrile. The hydrogenation process enhances the rubber's strength and durability by replacing some of the unsaturated double bonds with saturated single bonds. This results in improved resistance to heat, oil, and ozone compared to standard nitrile rubber.

Advantages of HNBR Rubber

- Excellent mechanical properties - HNBR rubber has high tensile strength, good tear resistance, and low compression set, which makes it ideal for sealing and gasket applications in harsh environments.

- Superior temperature resistance - HNBR rubber can withstand extreme temperatures, from -40°C to 150°C, without losing its mechanical properties.

- Chemical and oil resistance - HNBR rubber is resistant to many chemicals, such as acids, bases, and hydrocarbons, making it a popular choice for automotive and industrial applications.

Applications of HNBR Rubber

HNBR rubber is widely used in various industries, including automotive, aerospace, oil and gas, and industrial manufacturing, for its excellent performance properties. Some common applications of HNBR rubber include:

- Seals and gaskets - HNBR rubber is often used in high-temperature and high-pressure sealing applications, such as engine oil seals, valve stem seals, and O-rings.

- Automotive hoses and belts - HNBR rubber is used in the production of automotive hoses, belts, and timing belts due to its resistance to heat, oil, and other chemicals.

- Oil and gas drilling equipment - HNBR rubber is commonly used in oil drilling equipment, such as blowout preventers and drill bits, due to its superior chemical and temperature resistance.

- Industrial machinery - HNBR rubber is used in various industrial machinery applications, such as hydraulic seals, diaphragms, and conveyor belts, due to its durability and resistance to wear.

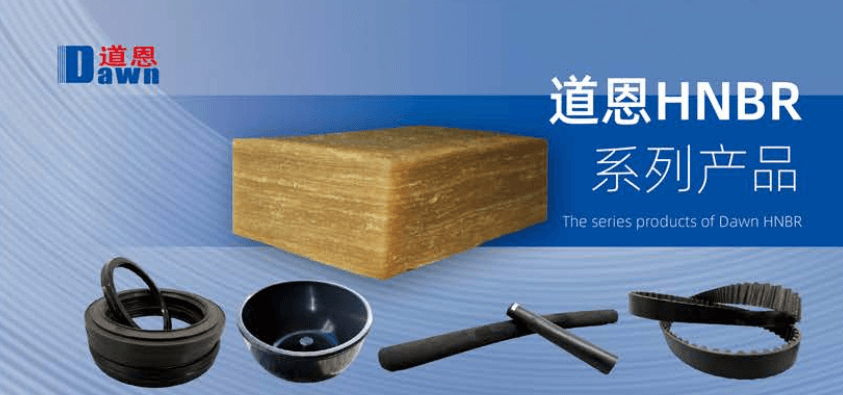

About Dawn's HNBR

Dawn is the professional and advanced HNBR rubber manufacturer in China, which adopts self-developed core catalysts. It has a designed capacity of 3,000 tons per year, and the first phase of 1,000 tons was officially produced in 2019. The hydrogenated nitrile rubber produced by Dawn has wide-ranging applications in high-end sectors such as automotive manufacturing, oilfield drilling, aerospace, and defense, such as oil exploration gaskets, new energy vehicle motor seals, automotive timing belts, refrigerant-resistant O-rings, and aircraft oil pipes.

In summary, HNBR rubber is a high-performance material with excellent mechanical, chemical, and temperature resistance properties. Its versatility and durability make it an ideal choice for various applications across many industries. If you are looking for a reliable material for your next project, take Dawn HNBR rubber into your consideration.